Publisher: Supplier of LED Display Time: 2023-09-14 18:42 Views: 2361

As we all know, GOB technology has become more and more widely used in the LED display industry in recent years, not only because it has brought a new evolution direction to the industry, but also has brought practical application to products in various industries. Real benefits, so what is GOB coating? Next, the editor of LCF will introduce to you what is the GOB coating technology of LED display.

GOB is the English abbreviation for GLUE ON THE BOARD. GOB coating technology is a new type of optical thermal conductive nano-filling material. The characteristic of this technology is to fill the gaps between the lamp beads on the PCB board of conventional LED displays, enhance the stability of the LED lamp beads, and solve the problem of LED displays that are prone to dead lights or lights falling off. In addition, GOB coating technology can also achieve a frosted effect on the surface of LED display screens, improve existing protection technologies, and innovatively realize the conversion and display of display point light sources from surface light sources.

The GOB process can truly meet the requirements of LED display product characteristics and ensure standardized mass production of quality and yield. It requires a complete production process, reliable automated production equipment that cooperates with production process research and development, and a customized pair. A mold with packaging materials developed to meet product characteristics.

So, what are the functional features and advantages of GOB-coated LED displays?

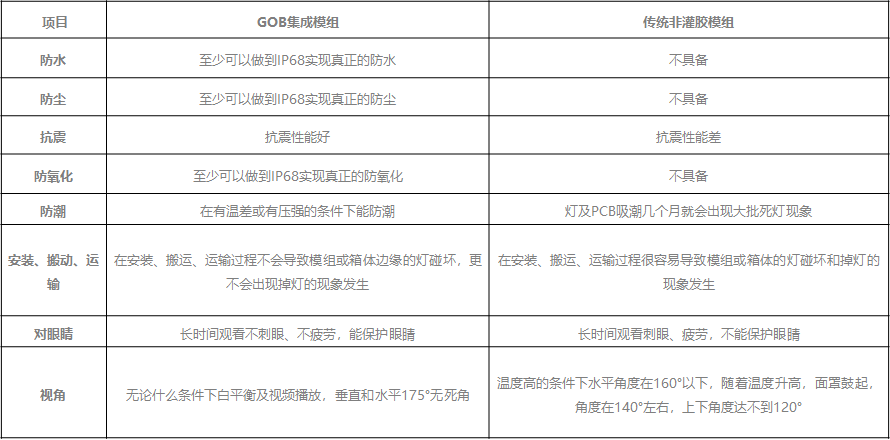

1. Better waterproof and moisture-proof performance: GOB coating technology adopts three-dimensional coating, comprehensive protection, and smooth and seamless surface, thus greatly improving the moisture-proof and waterproof performance.

2. Stronger dust-proof performance: GOB packaging completely prevents the intrusion of dust and other metal dust and powder, eliminating problems such as dead lights and column lights caused by short circuits.

3. Better anti-impact performance: GOB-encapsulated LED displays are anti-collision and easy to maintain, and have stronger pressure resistance, effectively extending the service life of the screen.

4. Better corrosion resistance: The GOB-encapsulated LED display will not be interfered by the outside world and has a good anti-salt spray effect.

5. Better optical performance: GOB package adopts matte coating optical diffusion technology, which makes the picture soft and non-glaring, effectively reducing blue light radiation and making viewing more eye-friendly.

6. Better heat dissipation performance: GOB packaging helps to dissipate heat, reduces the necrosis rate of lamp beads, and makes the screen more stable.

7. Wider viewing angle: Through GOB process, the screen emits more uniformly and the display effect is clearer and more transparent. And the viewing angle of the screen is greatly improved (up to 180°).

In general, the GOB-coated LED display has higher stability and better optical performance, can provide better protection and durability, has a wider viewing angle, and the display effect is clearer and more transparent. The indoor and outdoor full-color LED display products produced by LCF are all coated with GOB. In addition, LCF can also undertake the GOB coating business of LED displays. If you have relevant needs, please contact us at LCF and we will provide you with the best solutions and services. If you want to buy a large screen, contact LCF!