Publisher: Supplier of LED Display Time: 2022-12-01 10:49 Views: 1789

In recent years, LED display screens have been widely used in protective engineering, and strong ground shock vibrations will be generated in the project under the strike of weapons [1-2]. Once this shock vibration exceeds the allowable value of LED display screens [3], It will inevitably cause damage and destruction of the LED display in the project. In order to ensure the smooth command of the protection project in wartime, it is necessary to evaluate the impact resistance of the LED display in the project, give the allowable value of the LED display's resistance to explosion shock and vibration, and provide a scientific basis for the vibration protection of the LED display in the protection project. basis to ensure its safety. At present, there are few relevant research reports on the impact resistance of LED display screens at home and abroad. To this end, the author carried out experimental research on the anti-explosion impact performance of LED display screens to provide reference for its protection design. Next, Liancheng sent the editor to take everyone to take a look!

1 Selection of test samples

The impact life of the equipment has non-negligible randomness, and the selection of the test object will have a greater impact on the test results. At present, there are many brands and specifications of LED displays commonly used in the market, and their structural composition and connection methods are relatively different. big difference. The LED display screen includes the display body and its internal supporting components. Its interior is composed of a data receiving board, a power supply, and an installation substrate. Unified power supply for electrical equipment. When conditions permit, the best display effect can be achieved by adopting the rear maintenance method fixed by the back bracket. However, in order to save the installation space and facilitate the use and maintenance, etc., the installation method of pre-maintenance is also commonly used in current protection projects. The rear maintenance is connected with the structural frame by bolts, and the LED display screen of the front maintenance is connected with the structural frame by a magnet column, and its impact performance depends on the magnetic force of the magnet column. The impact resistance of the screen is good. The author carried out the impact performance test research on the front-maintenance LED display screen, and selected four kinds of front-maintenance LED display screens of different specifications and models commonly used in the project for the test.

2 Experimental research methods

The test equipment adopts the explosion shock vibration simulation test bench [4]. The plane width of the test bench is 1.7m×1.2m, and the maximum load is 2t. It can provide shock acceleration signals with approximate half-sine pulse waveform. The peak value range of the acceleration main pulse is 50~2000m/s, and the corresponding main pulse width is 45~5ms . The acceleration peak value is controlled by the impact air pressure, and the pulse width is controlled by the felt cushion layer with different thickness. The LED display screen is fixedly connected with the impact table through the supporting steel bracket, and installed on the LED display screen on the explosion shock vibration simulation test bench.

In order to make the impact test data of the LED display more accurate and reliable, the installed LED display is inspected for appearance, electrical performance and mechanical performance before the test, and the shock-sensitive parts are initially estimated. The installed LED display screen is subjected to vertical and horizontal impact tests, and the impact load in each test direction is divided into 4 test sections according to the impact pulse width τ, which are τ ≤ 10ms, 10ms<τ ≤ 20ms, 20ms< τ ≤ 30ms, 30ms<τ ≤ 40ms, the acceleration peak value of each test section is carried out from small to large, 4 test sections in 2 directions, if the number of samples in each test section is at least 3, at least 24 tests are required sample, the cost of such a test is too high. In order to save the test cost and carry out the test research normally, after each impact test, the equipment will be inspected and repaired, and damaged parts will be replaced without affecting the test results. Equipment is reused. During the test, the test data of each shot and the working status of the LED display are recorded. A total of 60 effective impact shots were obtained in the impact test.

Figure 1 LED display installed on the explosion shock vibration simulation test bench

Fig. 2 Typical horizontal acceleration input signal time history and frequency spectrum

Fig. 3 Typical vertical acceleration input signal time history and spectrum diagram

3. Test results

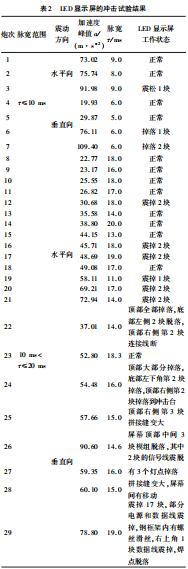

The specific test records of each shot are listed in Table 2.

表2 LED显示屏的冲击试验结果

4 Analysis of test results

4.1 Damage mode analysis

It can be seen from the test results that the front maintenance LED display module is mainly connected with the box structure or frame structure through the magnet column, and its shock resistance mainly depends on the magnetic force of the magnet column, and the magnetic force of the magnet column is limited, so the entire LED display The shock resistance of the screen is poor, especially the collision between the LEDs makes the LED lights fall.

The main damage modes of the LED display during the impact process are: the separation of the assembly, the falling off of the structural parts, and the loosening of the fasteners, etc. [5-10]. The main manifestations are: the screen shakes as a whole, the display module falls off; the cables of the display module are loosened and dropped; The main damage phenomena of the LED display screen during the impact process are shown in Figure 4.

Figure 4 Typical impact macroscopic damage of LED display

4.2 Analysis of allowable value of shock vibration acceleration

In order to obtain the allowable value of the shock vibration acceleration of the LED display screen, this test sets the normal working state of the equipment under the action of explosion shock vibration: after the test, any part of the test sample does not need human intervention, and maintains the original normal working state; The abnormal working state of the equipment under the action of explosion shock and vibration is set as follows: after the test, the test sample cannot complete its main function or the basic function is reduced, and other equipment used in conjunction with it cannot work normally, affecting its continuous working ability. The allowable value of the shock and vibration acceleration of the LED display is actually the explosion shock and vibration acceleration value that the LED display can withstand without damage.

During the impact test, if the LED display shows a black screen, flash point, signal interruption, module falling off, etc., it is an abnormal working state. According to the acceleration and action time measured by each shot, the relationship diagram is drawn, and "×" indicates abnormality Working status, "◆" means normal working status. Figure 5 shows the statistical results of the damage distribution of the LED display under the impact and vibration loads in different directions. The fitting curves in Fig. 5 are the critical curves of normal and abnormal LED displays under different impact and vibration. Under the same pulse width τ, as the peak value a of the shock and vibration load acceleration exceeds the critical curve, the abnormal state of the LED display increases significantly. Under the shock and vibration load with the same acceleration peak value, the damage degree of the LED display screen has a significant difference with the pulse width τ of the shock load. Therefore, the peak acceleration and pulse width of the shock and vibration load are important factors affecting the damage of the LED display screen. In order to ensure the safety of the LED display screen under the action of explosion shock and vibration, it is proposed to determine the values of a and τ that do not cause abnormal working conditions. Impact performance of LED display.

Figure 5 Damage distribution of LED display screen under shock and vibration load

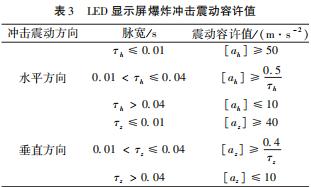

Combined with the shape of the critical curve in Figure 5, the critical curve can be divided into three sections according to the pulse width τ of the impact load [11]: τ ≤ 10ms, 10ms < τ ≤ 40ms and τ > 40ms. In order to give the allowable vibration value of the LED display screen under the action of explosion shock vibration in different directions, define [ az ] and [ ah ] as the allowable value of explosion shock vibration acceleration in the vertical direction and horizontal direction respectively, and τz and τh as the vertical direction and shock pulse width in the horizontal direction. Since the damage critical curve of the LED display screen decreases with the increase of the pulse width, the minimum value of the peak acceleration corresponding to different pulse width segments can be approximately taken as the vibration allowable value of the LED display screen in the direction of the explosion shock vibration.

Table 3 shows the permissible vibration values of the LED display for different explosion shock vibration directions and pulse width segments.

5 Conclusion

The following conclusions can be drawn from the above test results:

(1) From the shock and vibration test of the front maintenance LED display, it is obtained that the shock pulse width τ ≤ 0.01 s, 0.01 s < τ ≤ 0.04 s, τ > 0 in the vertical direction and the horizontal direction respectively .04 s vibration allowable value under the circumstances. It can provide reference for the protection design of LED display against explosion shock and vibration.

(2) The impact and vibration damage of the front maintenance LED display is mainly due to the falling off of the LED module. The LED module is connected to the frame by a magnet, and the magnet is easy to fall off under the action of shock and vibration.

(3) If you want to improve the anti-seismic performance of the LED display, you can change the magnet installation of the front maintenance to bolt fixing, and the anti-seismic performance of the LED display will be greatly improved.

(4) Due to the limitation of the test equipment, the prototype test of the large LED display screen combined with multiple modules cannot be carried out, but the analysis of its structure shows that with the increase of the combined modules, the seismic performance of the LED combined large screen will decline. .

The above is the knowledge of the experimental research on the anti-shock and vibration performance of LED display screens compiled by the editor of Liancheng. I hope it will be helpful to you. At the same time, you are welcome to add or correct. Lianchengfa is a world-leading provider of LED display applications and solutions, as well as a national-level professional and special new small giant enterprise. The main business covers four major sections: "Smart City", "Cultural Tourism Commercial Performance", "Commercial Display Engineering", and "Content Technology". It has the world's leading automated production equipment, modern post-doctoral research laboratories and comprehensive sales and services. team. Friends who want to buy LED displays can also contact us Lianchengfa led display manufacturer, a big country brand, trustworthy!

Source: Internet