Publisher: Supplier of LED Display Time: 2022-11-25 11:19 Views: 1672

Throughout the development history of LED display screens, lamp beads have been constantly updated and iterated. Since the LED display is an attribute of application-oriented innovation, it is no exaggeration to say that the change of its key device lamp beads leads to the change of the LED display, and the development of the lamp beads leads the development of the LED display. Next, Liancheng will take you to talk about LED display lamp beads.

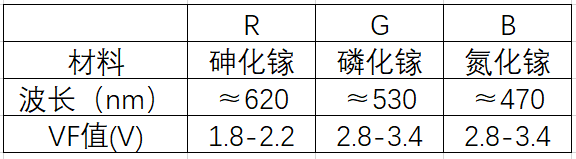

The LED display is full of brilliance, interpreting the colorful world and life. The colorful colors are actually only obtained by superimposing three colors of red, green and blue in different gray scales, so we call red, green and blue the three primary colors of the display industry. Different materials emit different light. The red, green and blue chips have the following differences due to different materials:

The size of the early light-emitting chips was about 10*13mil. In order to meet the production process requirements of display manufacturers, the upstream packaging factory would package them. From my entry into the industry until now, there are the following types of packaging in chronological order:

①In-line package (DIP)

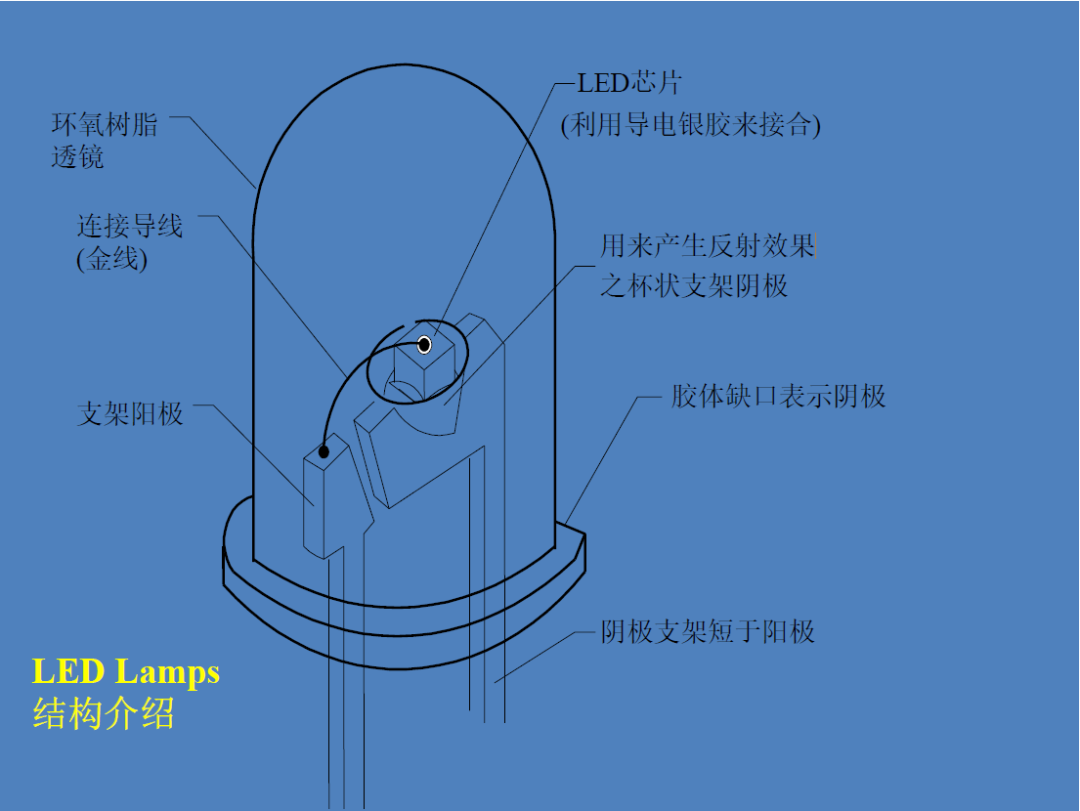

The picture above is a typical in-line lamp bead packaging diagram. The cathode of the LED light-emitting chip is fixed in the reflective cup of the cathode bracket through silver glue (conductive glue), the anode is bound to the anode bracket through gold wire, and then the whole is encapsulated by epoxy resin, thus forming an in-line LED lamp beads. The two brackets are respectively used as the positive and negative poles of the LED lamp bead, and it can be turned on only by electrifying the two poles.

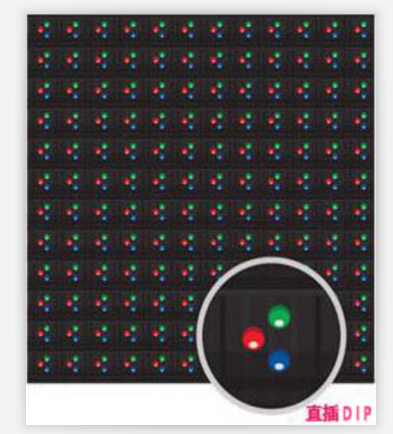

The LED display module made of in-line lamp beads is as shown in the figure below: because the chip used is large and its brightness is high, but it is expensive and the production efficiency is low, and the red, green and blue chips are separately packaged. The pixels are obviously granular and cannot achieve a smaller pitch. Its model has undergone shrinking iterations of 546, 346, and 246, but the minimum pitch that 246 can make is only about P7.62, and the unstable process is difficult, so the models of in-line lamp beads seen on the market are basically 346.

In order to solve the problems of large size and low efficiency of independent packaging of three lamp beads, a few manufacturers have introduced three-in-one packaged in-line lamp beads, because the production equipment of this lamp bead is different from conventional in-line lamp beads, and the production pass-through rate is different. High, currently only a few manufacturers in the industry are using it.

②Surface mount package (SMD)

As the spacing of LED display screens continues to shrink, SMD lamp beads have begun to be widely used, which are divided into two categories: TOP type and CHIP type.

1.TOP type

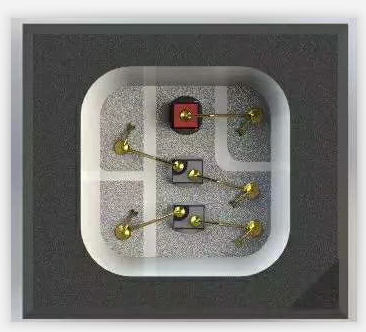

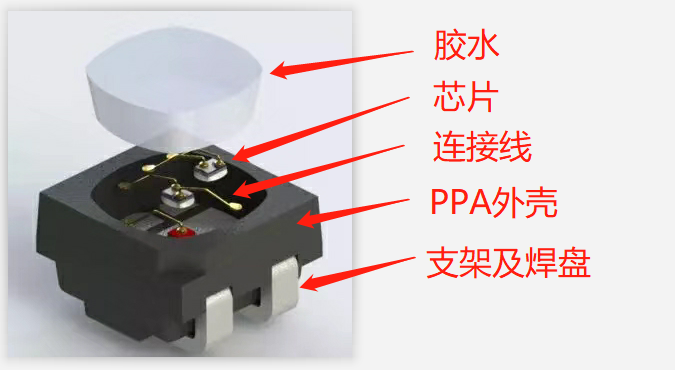

The TOP type is also called the bracket type, which packs three light-emitting chips of red, green and blue at the same time. As shown in the picture, one electrode of the red light chip is fixed by conductive glue and connected to the bracket, and the other electrode is tied to the bracket by gold wire. The blue-green light chip is fixed on the support of the red light chip through conductive glue, and the two electrodes are respectively bound and connected to the support by gold wires. (If the bracket where the chip is placed here is the positive pole of the chip, we call it a common anode lamp bead, otherwise it is a common cathode lamp bead). The PPA shell is sealed and forms a reflector cup, which is filled with a clear glue (usually epoxy) to allow light to escape. The bracket is bent at the bottom to form a patch pad.

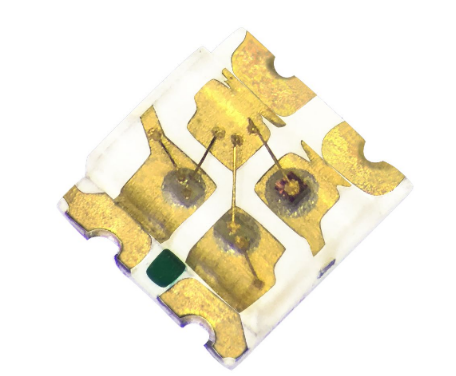

2. CHIP type

The size of the TOP type becomes smaller due to the limitation of the bracket. When the lamp bead becomes smaller to a certain extent, it can only be packaged in the CHIP type. At present, 1010 is a dividing line. The CHIP type is below 1010, and the TOP type is above 1010. There are both TOP and 1010. CHIP. As shown in the picture above, the bottom is a PCB substrate. The bracket in the TOP type becomes a PCB circuit in the CHIP type. The bottom pad is formed through a semicircular hole on the edge of the PCB substrate. The chip fixing method is not described in detail. The upper end of the chip is formed into a layer by molding process. Glue (usually epoxy).

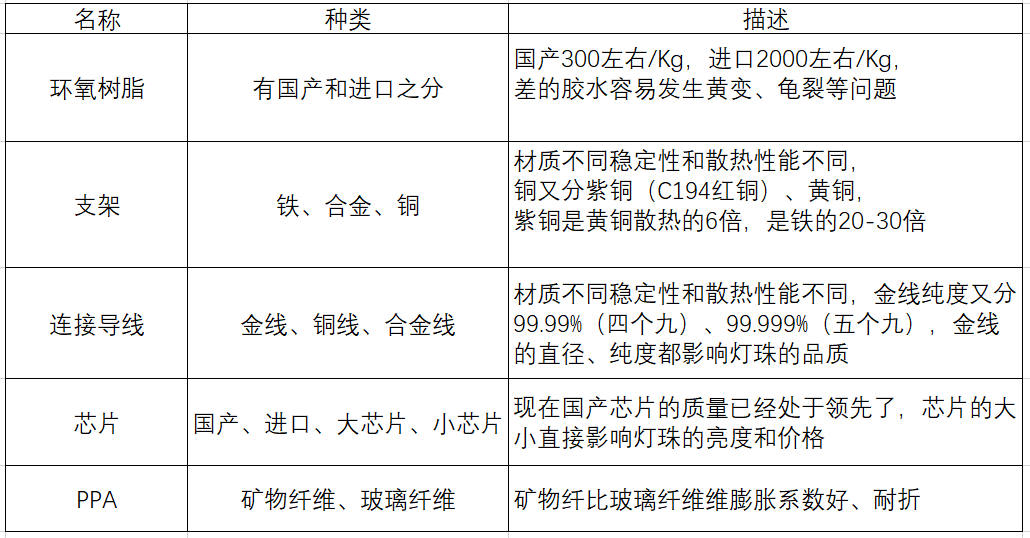

Regardless of the in-line lamp bead or the surface mount lamp bead, the price of the same package model can vary greatly, mainly because it is determined by the materials used, and the different materials have the following differences:

Source: LED Display Technology Sticker