Publisher: Supplier of LED Display Time: 2017-11-21 16:36 Views: 4433

1. Packaging technology: LED displays with density above P2 generally use lamp beads of 1515, 2020, 3528, and the shape of LED pins uses J or L packaging. When the pins are welded from the side, there will be reflections in the welding area, and the ink color effect is poor. It is bound to be necessary to increase the mask to improve the contrast. With further increase in density, L or J packaging cannot meet application requirements, and QFN packaging must be used. The characteristic of this process is that there is no lateral welding of the pins, and the welding area is non-reflective, so that the color rendering effect is very good. In addition, it adopts all-black integrated design and compression molding, the contrast of the picture is increased by 50%, and the picture quality of the display application is better than that of the previous display.

2. Soldering process: Too fast reflow soldering temperature rise will cause uneven wetting, which will inevitably cause the device to shift during the process of wetting imbalance. Excessive wind circulation will also cause displacement of the device. Try to choose a reflow soldering machine above 12 temperature zone, chain speed, temperature rise, circulating wind power, etc. as strict control items, that is, to meet the reliability requirements of soldering, but also to reduce or avoid component displacement, and try to control it within the required range. Generally, the range of 2% of the pixel pitch is used as the control value.

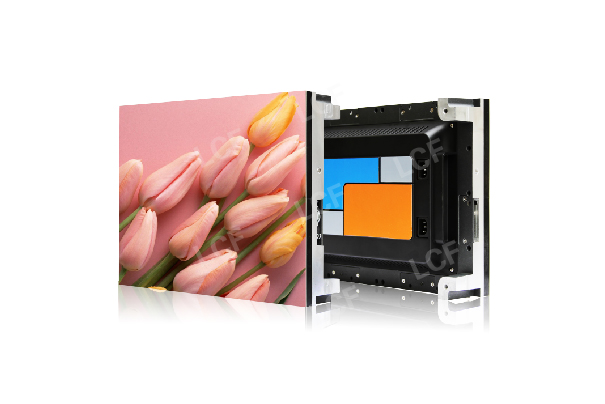

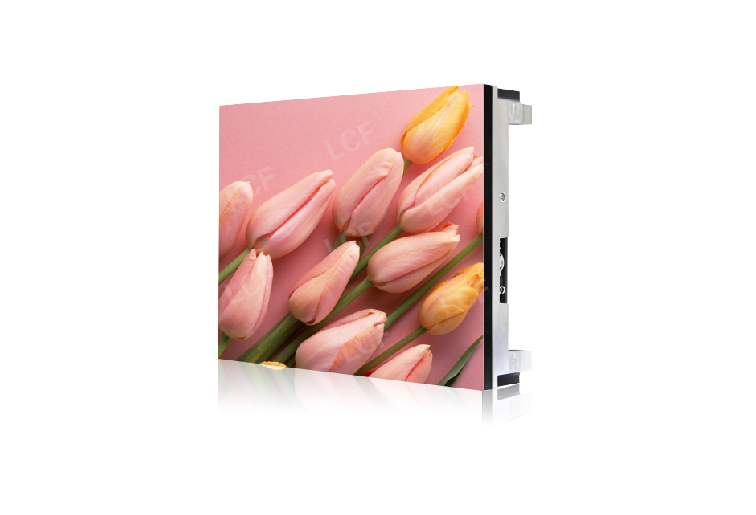

3. Cabinet assembly: The cabinet is made up of different modules. The flatness of the cabinet and the gap between the modules are directly related to the overall effect of the cabinet after assembly. Aluminum plate processing boxes and die-cast aluminum boxes are currently widely used box types, and the flatness can reach within 10 wires. The splicing gap between the modules is evaluated by the distance between the nearest pixels of the two modules. If the two pixels are too close, they will be bright. Line, two pixels too far will cause dark lines. Before assembling, it is necessary to measure and calculate the seam of the module, and then select the metal sheet of relative thickness as the jig to be inserted in advance for assembling.

4, screen assembly: the assembled cabinet needs to be assembled into a screen before it can display refined pictures and videos. However, the dimensional tolerance of the box itself and the cumulative tolerance of assembly cannot be ignored for the assembly effect of the micro-pitch LED display. If the pixel pitch of the nearest device between the cabinet and the cabinet is too large or too small, it will cause dark and bright lines to be displayed. The problem of dark and bright lines is a difficult problem that cannot be ignored and needs to be overcome in the current micro-pitch LED display. Some companies make adjustments by sticking 3m tape and fine-tuning nuts on the box body to achieve the best results.

5. Printed circuit board technology: With the development trend of micro-pitch LED displays, 4-layer and 6-layer boards are adopted, and the printed circuit board will adopt the design of micro-via and buried holes, and the printed circuit pattern will have fine wires and narrow micro-holes. Spacing, the mechanical drilling technology used in processing can no longer meet the requirements, and the rapidly developing laser drilling technology will meet the requirements of micro-hole processing.

6. Printing technology: Too much or too little solder paste amount and printing offset directly affect the welding quality of the micro-pitch LED display tube. The correct PCB pad design needs to be communicated with the manufacturer and implemented into the design. The opening size of the stencil and the correct printing parameters are directly related to the amount of solder paste printed. Generally, 2020RGB devices use electro-polished laser stencils with a thickness of 0.1-0.12mm. For devices below 1010RGB, it is recommended to use stencils with a thickness of 1.0-0.8. The thickness and opening size increase in proportion to the amount of tin. The quality of micro-pitch LED soldering is closely related to solder paste printing. The use of printers with functions such as thickness detection and SPC analysis will play an important role in reliability.

7. Mounting technology: The slight deviation of the position of each RGB device of the micro-pitch LED display will cause the display of the screen to be uneven, which will inevitably require the mounting equipment to have higher precision.

8. System card selection: The light and dark lines and uniformity of the micro-pitch LED display and the color difference are accumulative criticisms of LED device differences, IC current differences, circuit design layout differences, assembly differences, etc. Some system card companies can reduce the brightness through software correction Uneven lines, brightness and chroma.