Publisher: Supplier of LED Display Time: 2024-11-20 14:03 Views: 868

In today's ever-changing technology, LED display screen with its high brightness, rich colour, long life and other advantages, widely used in advertising, entertainment, transportation, sports events and other fields. Behind this, LED display factory is the birthplace of this magical visual products, they are like a manufacturing hall, a steady stream of quality products for the global market. LCF editor will be in this article for everyone to introduce the LED display factory factory layout and production process, production process, quality control and after-sales service.

First, the factory layout and production process

(A) carefully planned factory layout

LED display factory layout is usually carefully designed. The raw material warehouse is located near the entrance, which is convenient for loading and unloading and storage of raw materials. Here are stored a large number of LED lamp beads, driver chips, circuit boards, plastic shells and other basic materials, these raw materials are after strict quality inspection before being received.

The production workshop is the core area of the factory, which is generally divided into several parts according to the production process. First is the circuit board production area, where advanced printed circuit board (PCB) production equipment works in an orderly manner. Skilled workers through high-precision printing, etching and other processes, the complex circuit patterns printed on the substrate, for the subsequent installation of LED lamp beads to lay the foundation.

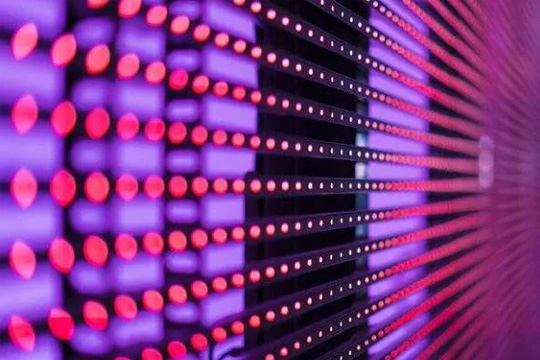

Next is the LED bead mounting area, where automated Surface Mount Technology (SMD) equipment is used to accurately mount a tiny LED bead onto a circuit board. These equipments are able to complete the mounting work with high speed and precision, ensuring the accurate position of each lamp bead and guaranteeing the high quality of the display.

The assembly area is where the circuit boards with the laminated lamp beads are assembled with other components. Workers skilled power supply, control module, heat sinks and other circuit boards connected, and installed on the shell, initially formed the prototype of the LED display.

(B) rigorous production process

Production process is the key to ensure the quality of LED display. Starting from the procurement of raw materials, the factory carries out strict screening and testing of each batch of materials. For example, the brightness, wavelength, colour rendering index and other parameters of LED lamp beads should meet the strict standards, and only qualified lamp beads can enter the production process.

In the circuit board production process, each process has a detailed quality control node. After the production of circuit boards need to be tested for electrical performance, check whether there are short circuits, circuit breakers and other problems.

After the LED lamp bead placement is completed, it should be lit test, through the special testing equipment, each lamp bead is tested one by one, to ensure that it is normal light emitting and colour consistency. After the assembly is completed, the whole display has to go through a series of aging test, waterproof test (for outdoor display), brightness and contrast test and so on. Aging test can detect potential quality problems in advance, so that the display in a long time stable operation, to ensure that the product can work reliably after delivery to the customer.

Second, technology research and development and innovation

(A) continuous investment in research and development strength

LED display factories know that technological innovation is the key to maintain competitiveness. Therefore, they usually set up special R & D departments and invest a lot of manpower and material resources in technology research and development. R & D team consists of electronic engineers, optical experts, software engineers and other professionals in various fields.

These professionals pay close attention to the latest developments in the industry and changes in customer needs, and constantly explore new technological directions. For example, they are committed to researching smaller pixel pitch technology to improve the resolution and display effect of the display. By continuously improving the packaging process of LED lamp beads and the design of circuit boards, the displays are able to present clear and detailed images even when viewed from a closer distance, to meet application scenarios such as high-end commercial displays and command centres, which have very high requirements for picture quality.

(B) the application of innovative technology

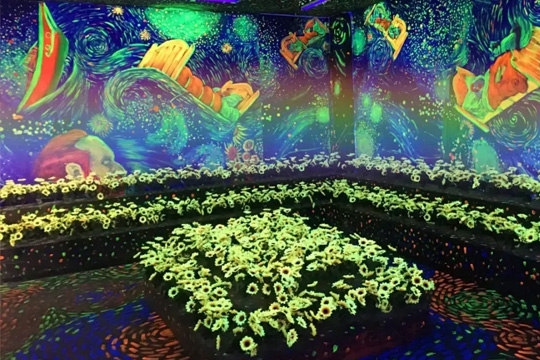

In the application of innovative technology, LED display factory has made many breakthroughs. Among them, flexible LED display technology is an impressive achievement. Through special materials and processes, the display can be bent, curled and other deformations, providing a new solution for creative display and special installation environment. This flexible display has been widely used in stage design, automotive interiors, architectural decoration and other fields.

In addition, high refresh rate and high grey level technology are also the focus of the factory's R&D. The high refresh rate can ensure that the display will not drag when playing fast-moving images, making the images smoother. High grey level can make the display show richer and more delicate colour transition and improve the visual experience. The application of these technologies makes the LED display in the live broadcast of sports events, large-scale outdoor broadcasting, and the LED display can be used for the broadcast of sports events.

Third, quality control and after-sales service

(A) strict quality control system

Quality is the lifeline of LED display factory. The factory has established a perfect quality control system, from the procurement of raw materials to the finished product factory, each link has strict quality testing standards and processes. In addition to the previously mentioned tests during the production process, the factory will also conduct random sampling tests on finished products to ensure that each batch of products can meet the high quality standards.

The quality control department is equipped with advanced testing equipment, such as spectral analysers, luminance meters, high and low temperature test chambers and so on. These equipments are capable of comprehensively testing the optical performance, electrical performance and environmental adaptability of the displays. For example, by simulating different environmental temperatures through the high and low temperature test chamber, the stability of the display in extreme environments is examined to ensure that the product can work normally under different climatic conditions.

(B) perfect after-sales service

After-sales service is an important guarantee for LED display factories to establish long-term cooperation with customers. Factory will usually set up a professional after-sales service team, to provide customers with a full range of technical support and maintenance services. In the product installation stage, after-sales service personnel will go to the site to guide the installation, to ensure the correct installation and commissioning of the display.

Once the customer encounters problems in the process of using, whether it is a hardware failure or a software setting problem, they can contact the after-sales service team in time. The after-sales service personnel will solve the problem quickly by remote diagnosis or on-site maintenance to minimise the impact on the customer's business. In addition, the factory will also regularly visit customers to collect customer feedback on the product, to provide a basis for product improvement and upgrading.

In short, LED display factory is a place full of technology and innovation, rigour and refinement. They through the scientific layout, advanced technology, strict quality control and perfect after-sales service, to create a high quality LED display products, for the global visual display field injected a constant stream of vitality, light up our colourful visual world.

The above is the LCF editorial to sort out the LED display factory factory layout and production process, production process, quality control and after-sales service, I hope to be helpful to you, while welcome to add or correct. LCF is a collection of research and development, intellectual property, sales, operation, service in one of the national speciality and new small giant enterprises, national high-tech enterprises. If you need to buy LED electronic display friends can also directly contact the LED display manufacturer LCF, big country brand, trustworthy!