Publisher: Supplier of LED Display Time: 2022-08-30 13:44 Views: 1433

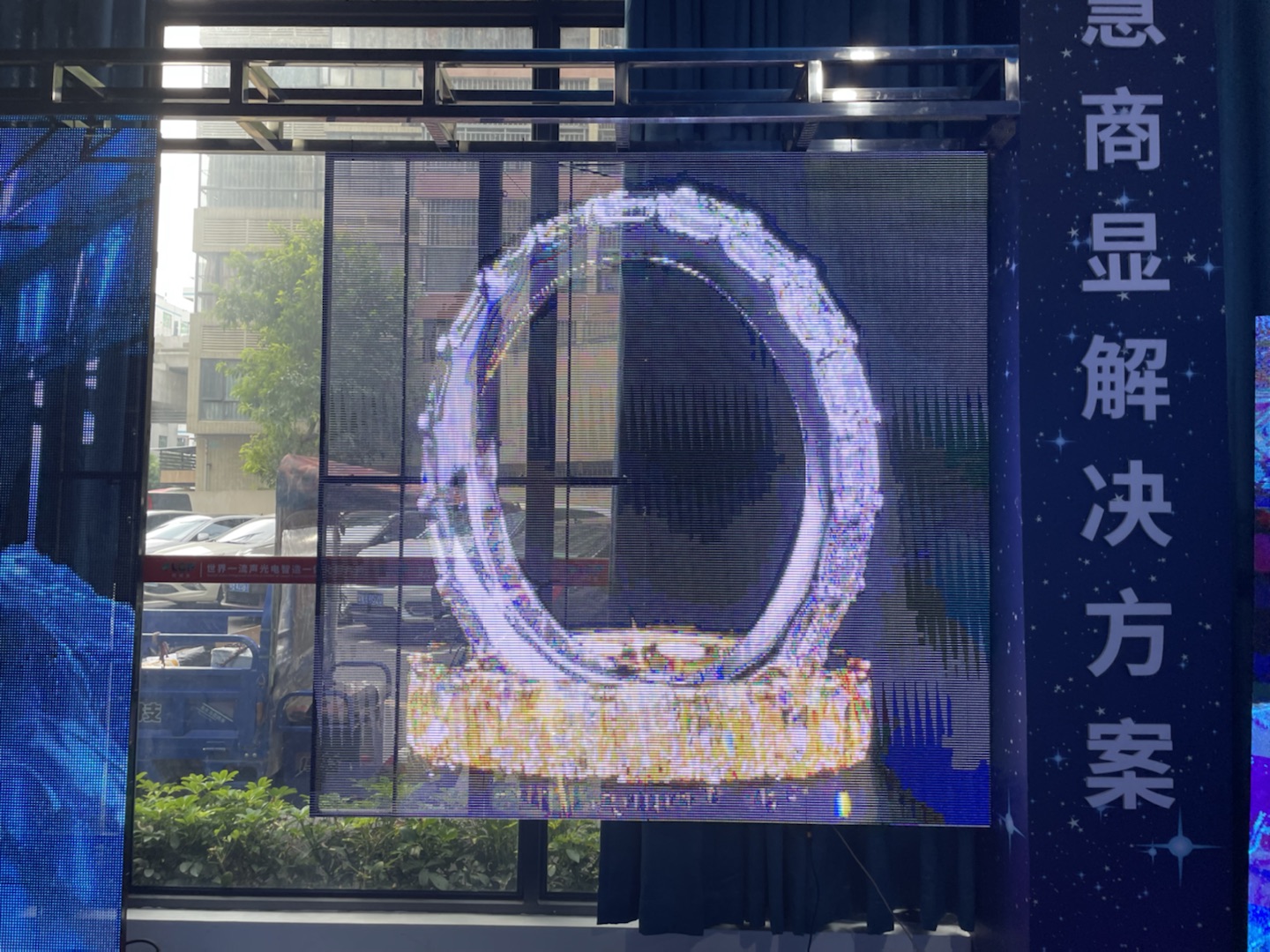

What is the production process and structure of transparent LED display? Common LED displays on the market generally use black substrates. Because the black substrate cannot transmit light, there is a problem of unsightly appearance. And there are certain limitations in the applicable occasions.

And the LED transparent screen just served the above topic. The principle of transparent LED display is a micro-innovation of LED light bar screen. Targeted improvements have been made to the patch manufacturing process, lamp bead packaging, and control system. In addition, the hollow design structure reduces the impact of structural components on the line of sight. Block, improve the permeability and lighting performance.

Below, LCF will send a small editor to tell you which of the following connection processes are used in the LED transparent screen:

1. Welding

The welding process is to weld the LED light bar to the transparent screen box. Art features: firm and stable

Remarks: In terms of stage and stage beauty, TV stations, concerts, large-scale cultural evenings and other fields are often disassembled frequently, so the stability and reliability of the screen body are very demanding, not easy to deform, and have better bump protection, so the welding process is generally selected. Transparent screen products.

2. Plug

The plug-in process is to plug the LED transparent screen light bar into the transparent screen box. The process features: a single light bar can be replaced at any time, which is very convenient for after-sales maintenance.

Remarks: In terms of engineering, in glass curtain wall, indoor atrium, sky curtain and other fields, after the screen is installed, the general structure and position are fixed, and maintenance is required quickly, so LED transparent screen products with plug-in technology are generally selected.

Summary: In the field of stage rental, welding is preferred for good stability; in the field of engineering, plug-in is preferred for after-sales maintenance. Did you remember?

The article is excerpted from Internet resources. If there is any infringement, please contact us to delete it in time. Thank you.