Publisher: Supplier of LED Display Time: 2022-02-10 16:04 Views: 1762

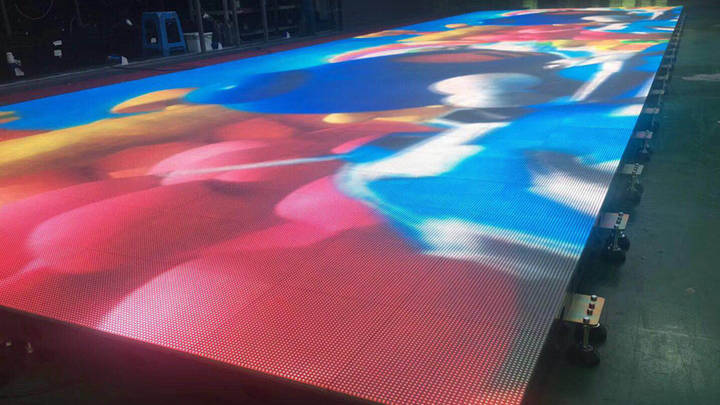

LED floor tile screen is a novel digital ground display device. Its response is based on new digital technology, using microcomputer full digital processing, advanced circuit protection equipment, and video synchronization control to achieve high-resolution soft color display It completes the perfect combination of stage virtual landscaping and performance interaction; it adopts a high-strength tempered glass mask and a sturdy die-casting aluminum alloy supporting device. The LED floor tile screen is an LED display specially designed for ground display. It has been specially designed in terms of load-bearing, waterproof performance, and heat dissipation performance, so that it can adapt to high-intensity trampling and operate normally for a long time. Next, the editor of LCF will lead you to understand the relevant characteristics, technical principles and installation methods of LED floor tile screens.

Features of LED floor tile screen:

1. Fast and flexible installation: direct installation without tools or rail installation.

2. High load-bearing performance: aluminum alloy material structure, the high load-bearing capacity per square meter can reach 1.5 tons.

3. Excellent maintenance performance: can be directly exchanged without removing the adjacent box.

4. High contrast design: technical design mask, clear playback effect.

5. Outstanding low-brightness and high-gray effect, showing uniform grayscale and good consistency.

Technical principle of full color LED interactive floor tile screen:

1. The multimedia interactive system consists of image motion capture device, data transceiver, data processor and LED floor tile screen.

2. The image motion capture device realizes the capture and collection of participants' images and motion data.

3. The function of the data transceiver is to realize the express transmission of data back and forth between motion captures.

4. The data processor is the core part that realizes the real-time interaction between the participants and various effects. It analyzes and processes the collected image and motion data, and combines it with the data inherent in the processor.

Installation method of LED floor tile screen:

1. Consider according to the process method: understand the characteristics of the structure form, structure weight, installation height, span, etc., and try to choose a mature and advanced installation process according to the actual situation on site.

2. Considering according to the lifting equipment: first, choose the own equipment, make full use of the lifting equipment on site, and then rent it nearby. General situation: when the number of components is small, truck cranes are mostly used; small and medium-sized truck cranes are mostly used for gantry rigid frame hoisting; when the installation period is long, the installation height and the turning radius are large, crawler cranes are more economical than truck cranes; overall Hydraulic synchronous hoisting (jacking) devices are mostly used for hoisting and sliding; tower cranes are generally used for the installation of medium and high-rise steel structures; gantry cranes and bridge erecting machines are mostly used for ordinary bridge installations.

3. Flip-chip construction - The flip-chip method is a special installation process that is first up and then down. It is suitable for structures with large height-to-width ratios, such as steel towers, masts and other structures. When conventional cranes are difficult to hoist close to each other, the flip-up method is generally used. When adopting this method, it is necessary to focus on the overall stability of the structure and the stability of the equipment itself during the installation process, and there must be reliable support and stabilization measures.

4. Structural slip method - The structural slip method has been developed to the use of hydraulic jacks and computer synchronous control technology, which is a step more advanced than the past grid slip method. Its applicable conditions are: first, due to site conditions, cranes and support frames cannot be installed in the span; second, the structural support conditions are conducive to laying the slip track; third, the strength and The stiffness all meet the requirements; fourth, understand the form and fixing method of the structural support; fifth, the longer the longitudinal slip route, the higher the efficiency.

5. Support frame sliding method - its applicable conditions are that it occupies the site within the span, the installation height is low, the structural area is large, or the longitudinal length is long. First, when the installation height is below 15 meters, ordinary fastener-type steel pipe scaffolding or bowl-mouth scaffolding can be used as the support frame; second, when the frame body is high and the bearing capacity is large, the steel support frame should be used. No matter which scheme is adopted, in addition to the requirements of the specification, the horizontal dynamic load should also be considered in the design calculation, and if necessary, large diagonal braces should be added to improve the overall stability.

6. Overall lifting method - The overall lifting method currently adopts computer synchronous control and hydraulic lifting equipment developed by Tongji University. This process gradually replaces the through-core motorized lifting and jack lifting schemes. The equipment is light and the technology is advanced. Its applicable conditions are: first, occupy the site within the span; second, the installation height is higher; third, the components are heavier; fourth, it is limited to vertical hoisting and cannot be displaced horizontally. That is, the higher the installation height, the heavier the lifting weight, the better the effect.

7. Earth method hoisting - Earth method hoisting is the use of single-angle bar, herringbone frame, rolling machine, pulley block, etc. as lifting equipment for structural hoisting. It is suitable for projects with heavy components, small number and high installation height. . Due to the increasing number of large-tonnage lifting equipment and advanced installation techniques, there are fewer and fewer local hoisting.

8. Rotation method construction - This method is mainly used for bridge installation. Due to the influence of railways, highways, and special environments such as mountains and rivers, when other bridge construction methods are limited, the rotation method is mostly used for construction.

9. The overall lifting method - it is basically similar to the overall lifting method, but the lifting equipment is different, and it is suitable for small and medium-sized structure installation. In the early days, multiple monopods or herringbone frames, winches, pulleys and cable wind systems were used for large-tonnage hoisting. Now, due to the large number of large-tonnage cranes, multiple cranes are selected for centralized lifting and installation for small and medium-sized projects as needed.

LCF recommends that you choose the appropriate load-bearing and pressure-resistant capacity and protection level according to your needs when purchasing LED floor tiles, and try to choose floor tiles that support interactive functions in shopping malls, department stores and other places to increase the fun and attract customers. It is recommended that you choose LCF LED floor tile screen. The big manufacturer has quality assurance, on-demand design, and perfect after-sales.