Publisher: Supplier of LED Display Time: 2024-11-25 16:06 Views: 1267

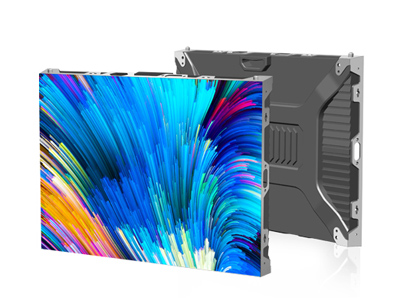

In today's era of rapid dissemination of digital information, LED display screen with its high brightness, bright colours, wide viewing angle and other advantages, widely used in outdoor advertising, shopping malls, stage performances, stadiums, traffic hubs and many other scenes, becoming a key medium for conveying visual information. However, as with all electronic devices, LED display screen is inevitably encountered faults, mastery of maintenance skills, can make it quickly revitalised, continue to shine. The following is a systematic LED display maintenance tutorial prepared by LCF.

Prelude to troubleshooting: observation and preparation

At the beginning of the maintenance, meticulous observation is the first step to ‘find the cause of the disease’. In the safe power-off state, close to the display, see whether the panel has physical damage, such as lamp bead rupture, bump marks, water stains, stains erosion and other visible problems; and then powered on, in the normal viewing distance to review the display screen, pay attention to whether there is a bad point (often black or abnormal colour single point), colour block (local colour unevenness, block abnormalities), bright line (vertical and horizontal through the screen abnormal bright line), screen (messy colour) and other phenomena, simultaneous monitoring and control of the LED display. (pattern) and other phenomena, simultaneous listening to abnormal sounds, such as current ZiZi sound, fan whistling sound, etc., these clues is to lock the failure of the ‘culprit’ key clues.

Maintenance tools must be prepared before the complete, screwdriver (cross, a word, to match the screen body screw specifications) to dismantle the shell, frame; multimeter is the detection of circuit ‘magic weapon’, can measure the voltage, current, resistance, to determine the line through the good or bad and electronic components; soldering iron, soldering wire used to weld loose or broken soldering; tweezers are convenient to clip small Parts; clean soft cloth, anhydrous alcohol specialised in cleaning lamp beads and circuit boards dirty; spare lamp beads, capacitors, resistors, driver chips and other commonly used components are ‘blood’ inventory, to deal with component damage replacement.

Common hardware failure repair: lamp bead, circuit board and power supply

Lamp bead failure in the first place, a single or a small number of lamp bead necrosis will be bad, dark spots, affecting the fineness of the screen. After locating the bad lamp beads, use tweezers to carefully pry away from the mask protection, precise heating of the old lamp beads soldering point (soldering iron 300 - 350 ℃), to be removed when the solder melts, clean up the pad, the same type of new lamp beads dipped in tin to insert the pins, weld firmly, pay attention to the operation of positive and negative corresponds to the end of the review of the display. If the problem is a large area of lamp beads, consider the quality of the lamp bead batch or power supply abnormalities, check the power supply lines and driver chip output.

Circuit board faults more hidden but tricky, line short circuit will burn off the copper foil to some areas of the black screen, with a multimeter ‘beep file’ along the line to measure through the broken, broken at the scraping insulation, solder bridge repair; capacitance bulging, leakage damage affecting the stability of the power supply, signal transmission, identification of the withstand voltage value, capacity parameters and replace with a new one; chip overheating, over-voltage breakdown will be Caused by overheating, over-voltage breakdown will cause screen and other chaos, with experience or professional equipment diagnosis, hot air gun assisted (350 - 400 ° C) disassembly and replacement, the operation needs to be extremely cautious to prevent damage to peripheral components.

Power supply module such as the ‘heart’, failure to make the whole machine ‘stop’. No power output, first check whether the fuse is blown, yes, then check the back stage short circuit for fuse restart; non-insurance issues, measure the input and output voltages, inconsistent with the nominal value (such as the common 5V, 12V output deviation of more than 10%), overhaul the rectifier bridge, filter capacitors, switching tubes and other components, replace the damaged parts, clean up the dust and re-tune the voltage, to ensure a stable power supply.

Software and signal failure response: calibration and connection

Software setting deviation can lead to display abnormality, such as computer control software parameter mismatch, resolution, refresh rate does not match the screen specification, the screen stretching, flickering or lagging, enter the software interface according to the screen manual to reset the parameters, select the right model, pixel pitch, scanning mode, etc., one by one to debug the screen to a clear and smooth; intelligent control card program disorders, you can try to reset and reboot, update the firmware, to restore the normal initial command output, to protect the signal accurate transmission. Accurate signal transmission.

Signal transmission link ‘off the chain’ is also a disaster, HDMI, DVI, VGA cable loosening, oxidation, damage, triggering black screen, screen, no signal prompt. Re-plugging cables, clean the interface gold finger, change the line to verify; receiving card, sending card failure to interrupt the signal ‘relay’, observe the card on the status of the indicator (always on, flashing rules corresponding to the fault code), targeted replacement or repair, troubleshooting the card slot contact, so that the data unimpeded in the equipment between.

Maintenance finishing and prevention: test and maintenance

Repair is complete, simulate the actual working conditions of multi-time, multi-content testing, playback of high-definition video, static graphics to check the colour, brightness, clarity, stability, after a few hours of ‘grilling’, no recurrence of abnormalities before the completion of the work.

Daily maintenance is a ‘precautionary’ approach, regular cleaning of the screen body, soft cloth dipped in alcohol to gently wipe the lamp beads, mask, dust and moisture; check the ventilation and heat dissipation, clearing the dust of the fan, to ensure smooth air ducts, to prevent overheating; pay attention to the operating environment, temperature and humidity, voltage fluctuations, with a voltage stabiliser, dehumidifiers, according to the use of time and frequency of the development of component replacement plan to extend the Display life, cut down the frequency of failure, so that it lasts to bloom in multiple scenes. Master this maintenance ‘secret’, LED display will be able to quickly return to the bright under the haze of failure, stable bearing information dissemination mission.

The above is the LCF editorial to everyone to sort out the system of LED display maintenance tutorial, I hope to help you, at the same time you are welcome to add or correct. LCF is a collection of R & D, manufacturing, sales, operation, service in one of the national speciality and speciality of new small giant enterprises, national high-tech enterprises. If you need to buy LED electronic display friends can also directly contact the LED display manufacturer LCF, the big country brand, trustworthy!